SmartMotor Provides Complete Motion Control Solution

Spooling is the most effective way to provide convenient packaging for materials of exceptionally long length. Typically spooling material is fed at a certain rate while the material traverses back and forth corresponding to the desired pattern.

The traversing position accuracy of a winder is best maintained when it's linked to the rotational velocity of the winding spool and SmartMotor™ technology makes perfect spooling simple. While the diameter of the spool changes, a SmartMotor™ uses “electronic gearing” to ensure the winding maintains its proper shape. Common problems such as overtravel are completely eliminated with this closed loop control capability.

The Closed-loop system also delivers precision. By monitoring the position error between the encoder and PID within the SmartMotor™ servo's electronics, a critical tension level can be set. At a constant tension setting, the SmartMotor™ will automatically adjust the spool speed based on the diameter of the spool.

Multiple nodes are one of the many reasons the modular design of SmartMotor™ worked so well for this application. Some of the winders that Independent Machine Company designs have up to 26 positions! With on-board memory available for hundreds of preset programs and drivers for various HMI’s, the ease of use of an Animatics SmartMotor™ becomes clear.

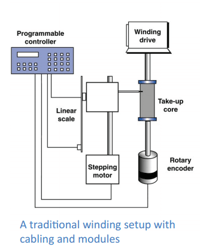

Advantages of the integrated nature of the SmartMotor™ are obvious when compared to a conventional servo driven winding system, seen below. With traditional systems, several drives, controllers, motors, and extensive cabling are often needed. Conversely, the Animatics SmartMotor™ is a complete motion control solution. The controller, drive amplifier, and encoder are all integral to a SmartMotor™.

Download the PDF version of this case study here.